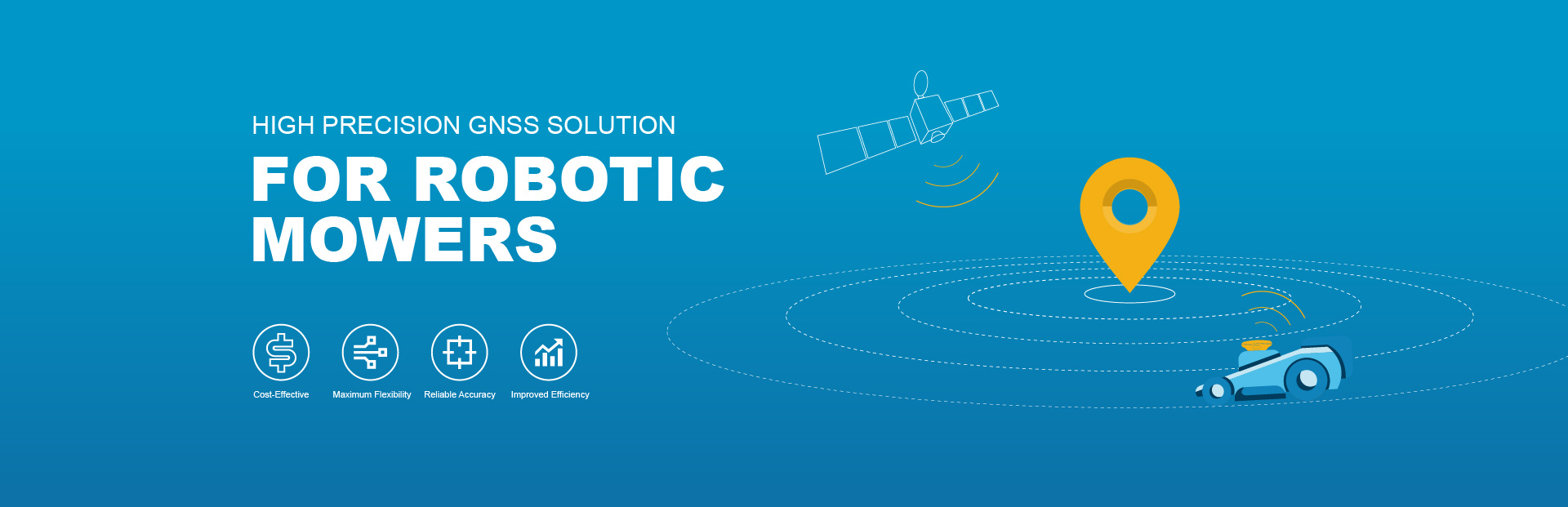

Cost-effective and highly flexible GNSS solution for robotic lawn mower

Overview

The utility of GNSS technology in robotic mowers has emerged as a way to optimize mowing efficiency and accuracy. Historically, robotic mowers operated autonomously by using the local CORS or self built CORS is of high cost and continuous maintenance input. With ComNav Technology’s current robotic mower solution, it is accessible to benefit from reliable high precision service easily and cost saving- with zero operational input and highly integrated design.

Challenges

One of the greatest challenge is accuracy and signal reliability, particularly in areas with poor satellite coverage or in areas with dense tree cover. These issues can impact the ability of GNSS technology to accurately guide the lawnmower and may require additional technology to be incorporated into the system to compensate for these challenges.

Another key challenge is the cost of implementing GNSS technology into lawnmowers. Even though the cost of hardware has decreased significantly in recent years, the operational input like subscription fees to CORS network definitely increase the overall cost of the robotic mower, making it less accessible to consumers.

There is also challenge with regulatory compliance. Some areas are strict regulations around the use of radio frequencies and power. Lawmakers are concerned about potential interference with other communication systems.

RTK is one of the popular method to deliver centimeter accuracy positioning in robotic mower solutions. User end can acquire correction data from a single base, local or self-built CORS. However, it is limited in wide use due to continuous investment and less accessibility to all users. When you build own CORS, the initial input is not affordable. ComNav team sought to put forward a solution with less cost and high flexibility and reliability in terms of investment and performance.

Solution

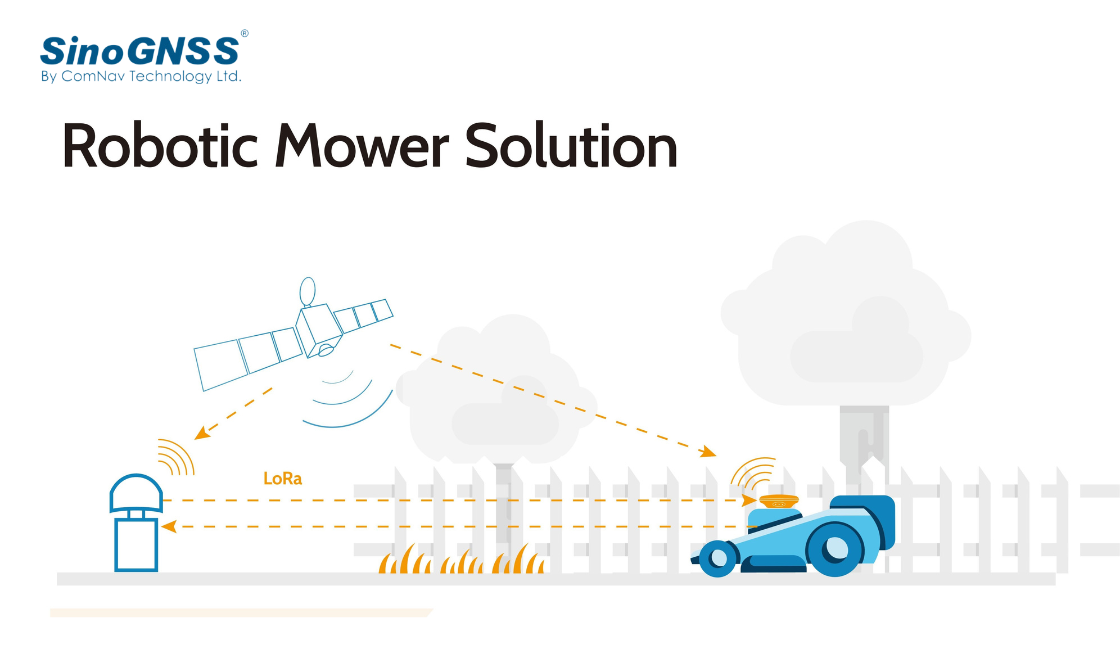

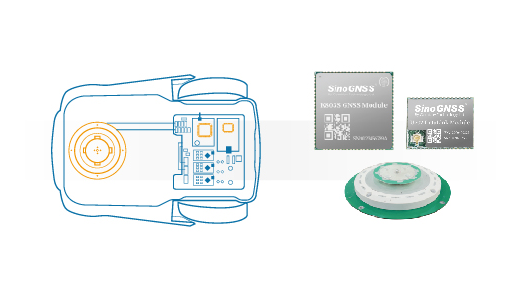

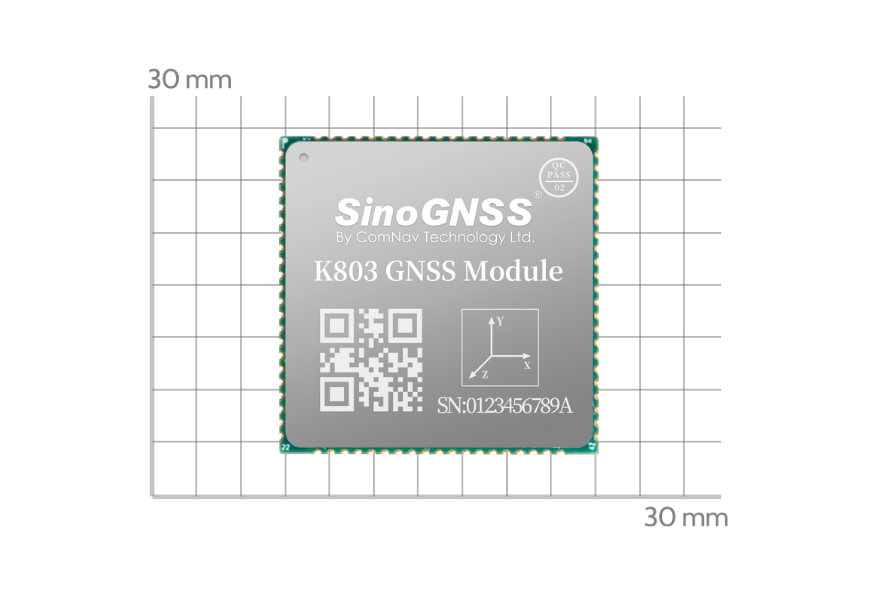

The main hardware of a robotic mower solution consist of U702 datalink module, 803S GNSS module and LoRa GNSS combination antenna, involving the whole process from satellite signal reception, differential data broadcasting and reception and RTK positioning data output.

|

|

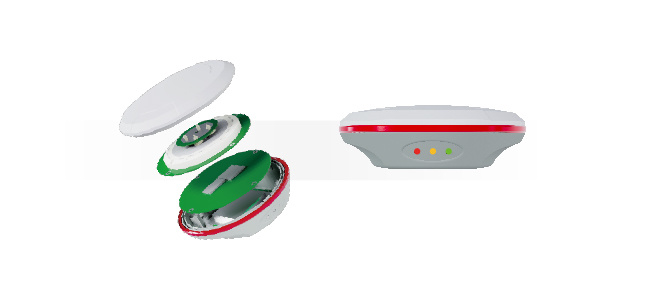

Intelligent GNSS Antenna | OEM Solution |

This is a ready-to-use solution, which can be directly used after being integratedinto the lawn mower robot without any further configuration. | This is a ready-to-integrate solution, consisting of a main board and a GNSS and Lora combination antenna, which is easily adaptable to specific needs. |

Advantages

Robotic mowers often operate in areas with poor GNSS signal coverage, such as regions with significant tree cover or corners. To ensure reliable accuracy in these situations, we employ the U702 LoRa data link module to receive correction data. This can reduce or delay the reception of RTK correction data, resulting in more stable RTK solutions. Furthermore, the U702 provides a more reliable connection to the RTK correction data source, reducing the risk of data dropouts or interruptions. As a result, this solution ensures centimeter-level accuracy in all conditions

So far, there are still barriers in using different types of RTK data across regions. The U702 data link module ensures flexibility in terms of the type of RTK correction data that can be received. Therefore, this solution can be easily integrated into existing systems or added to current devices without any physical changes, making it ideal for users and working consistently across manufacturers of mowers in different regions.

Historically, cost has been one of the key issues when using GNSS technology in robotic mowers. Backed up by years of GNSS technology experience, ComNav has successfully made it more affordable. Firstly, the hardware price is cheaper than traditional solutions. Secondly, by using the data link module as the correction data receiver instead of CORS, integrators can save costs in system updating and maintenance.

Combining with controller, this high precision solution makes it possible to eliminate the cumbersome installation of boundary wires and random movements. It allows for the generation of a virtual lawn line, route planning, and obstacle avoidance, enabling small lawn mowers to be used for cutting large areas.

Applications

About ComNav Technology

ComNav Technology develops and manufactures GNSS OEM boards and receivers for high precision positioning demanded applications. Its technology already been used in a wide range of applications such as surveying, construction, machine control, agriculture, intelligent transportation, precise timing, deformation monitoring, unmanned system. With a team dedicated for the GNSS technology, ComNav Technology is trying its best to supply reliable and competitive products to worldwide customers. ComNav Technology has been listed on the Shanghai Stock Exchange (Science and Technology Board), securities :ComNav Technology (Compass Navigation), Stock code: 688592.

About SinoGNSS®

SinoGNSS® is the official trademark of ComNav Technology Ltd., registered in People's Republic of China, EU, USA and Canada. All other trademarks are the property of their respective owners.

About ComNavTech®

ComNavTech® is the official trademark of ComNav Technology Ltd., registered in People's Republic of China, EU, USA and Canada. All other trademarks are the property of their respective owners.

About ComNav Technology

ComNav Technology develops and manufactures GNSS OEM boards and receivers for high precision positioning demanded applications. Its technology already been used in a wide range of applications such as surveying, construction, machine control, agriculture, intelligent transportation, precise timing, deformation monitoring, unmanned system. With a team dedicated for the GNSS technology, ComNav Technology is trying its best to supply reliable and competitive products to worldwide customers. ComNav Technology has been listed on the Shanghai Stock Exchange (Science and Technology Board), securities :ComNav Technology (Compass Navigation), Stock code: 688592.

About SinoGNSS®

SinoGNSS® is the official trademark of ComNav Technology Ltd., registered in People's Republic of China, EU, USA and Canada. All other trademarks are the property of their respective owners.

About ComNavTech®

ComNavTech® is the official trademark of ComNav Technology Ltd., registered in People's Republic of China, EU, USA and Canada. All other trademarks are the property of their respective owners.